Chapter 5 Breakdown: Pick an Idea That Can Scale — Why Growth Potential is Non-Negotiable

Series: Start. Scale. Exit. Repeat. Reflections | Author: Brent Parker, Resilience Repurposed LLC

📈 Welcome to Chapter 5 of the Start. Scale. Exit. Repeat. Reflections Series

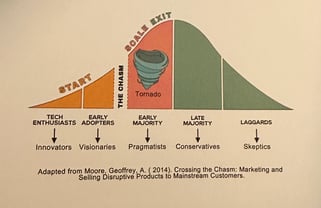

Not all businesses are created equal — especially when it comes to growth. In Chapter 5, Colin Campbell breaks down what it really means to build a scalable business and how to choose an idea that can grow without breaking you.

In this chapter, we explore different business models, their scalability ratings, and how to rate your own idea to determine whether it has room to expand — or if it’ll trap you in a hamster wheel of hustle.

⚖️ Scale Comes With Trade-Offs

Campbell warns that scalable businesses often require more upfront effort and risk, but the upside is exponential. On the flip side, unscalable businesses tend to cap your freedom and profits (Campbell, 2023).

📊 Scalability Rating System

Campbell presents a simple 1–5 rating system to evaluate the scalability of your idea:

- 1 – Brick-and-Mortar: Restaurants, schools, retail. Challenges: High overhead, location-dependent.

- 2 – Time & Materials: Consulting, services. Challenges: Limited by labor, not easily repeatable.

- 3 – Product/Service-Based: E-commerce, online training. Challenges: Inventory, fulfillment, production delays.

- 4 – Recurring Revenue: Subscriptions, SaaS. Challenges: Customer retention, initial build costs.

- 5 – Digital Assets: AI content, domain marketplaces, scalable platforms. Challenges: Global competition, market saturation.

💡 Rate Your Own Idea

Use Campbell’s chart as a sanity check. If you’re pursuing a 1 or 2, be aware of the constraints. If you’re aiming for a 4 or 5, gear up for early investment and longer development time — but with potentially massive returns.

🎯 The More Scalable, the Higher the Risk — and Reward

Campbell makes it clear: you can build a great business at any level. But if your vision includes freedom, passive income, or an eventual exit — scale has to be baked in from the beginning.

💡 Final Takeaway:

Chapter 5 is about being honest. Are you building something that frees you or something that traps you? Use the rating chart, get real about your goals, and make your decision with eyes wide open.

🔁 Coming Next: Chapter 6 – Can You Build a Moat Around Your Idea?

We’ll shift focus from growth to defensibility. How do you protect your business from copycats, competition, and collapse?

💬 Share Your Score

What’s your business idea’s scalability rating? Post it or tag me on LinkedIn @Brent Parker — and let’s compare notes.

📚 References (APA Style)

Campbell, C. C. (2023). Start. Scale. Exit. Repeat. Wiley.