How to Choose the Right 3D Printing Material

In this post, we discuss different material options for 3D printing. Keep reading to learn more.

How to Choose the Right 3D Printing Material

Introduction

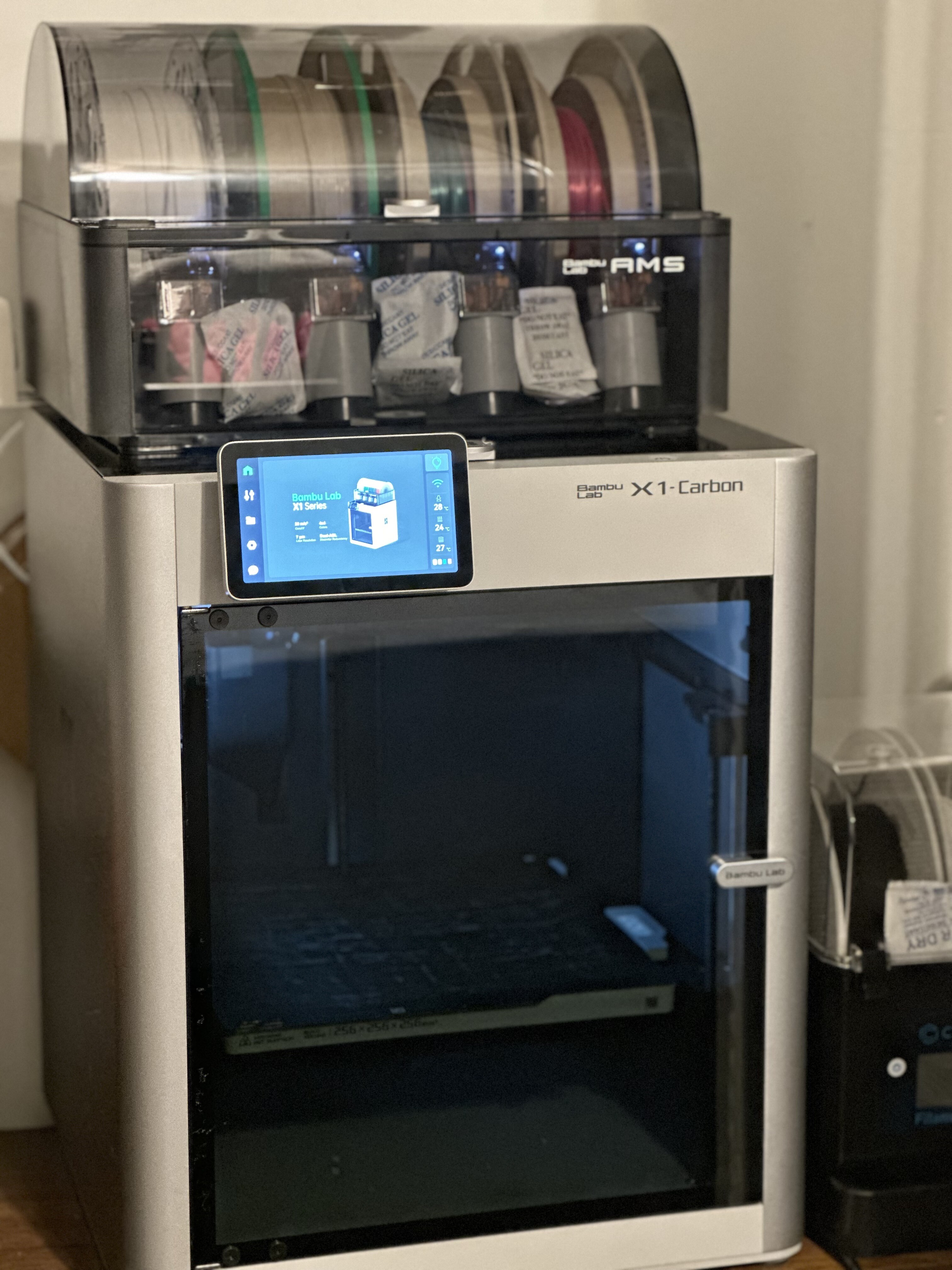

Choosing the right material for 3D printing isn’t just about picking what’s available—it’s about finding the perfect match between your design, application, and budget. Whether you’re printing a functional prototype, a consumer product, or an artistic display, the material you select plays a critical role in determining the strength, appearance, and performance of the final part (Gibson, Rosen, & Stucker, 2021). This article breaks down the most common types of 3D printing materials, their benefits, limitations, and how to make wise choices based on your project’s needs.

The Big Four: Plastics, Resins, Composites, and Metal Filaments

Thermoplastics: The Everyday Workhorse

Thermoplastics are the most common materials in 3D printing, especially for Fused Deposition Modeling (FDM) printers. Popular options include:

PLA (Polylactic Acid) is easy to print, biodegradable, and cost-effective. It is ideal for prototypes, decorative items, and non-functional parts.

ABS (Acrylonitrile Butadiene Styrene) is stronger and more heat-resistant than PLA but is prone to warping without a heated bed. ABS is common in automotive parts and functional prototypes.

PETG (Polyethylene Terephthalate Glycol) is a material that combines strength, flexibility, and minimal warping. It is excellent for parts exposed to moderate stress and wear.

Photopolymer Resins: High Detail and Smooth Finish

Resins are primarily used in SLA (Stereolithography) and DLP (Digital Light Processing) printers. They offer excellent surface finish and detail resolution.

- Standard Resin: Great for highly detailed models, miniatures, or display pieces.

- Tough Resin: Offers better impact resistance for functional parts.

- Flexible Resin: Used for parts that require bending or slight deformation.

Resin prints typically require post-processing (washing and UV curing) but offer unmatched detail (Criswell, 2020).

Composite Filaments: Strength with a Twist

Composites are filaments blended with other materials to enhance mechanical properties or visual appeal.

Carbon Fiber-Filled Filament is exceptionally rigid and lightweight, ideal for drones, RC components, and structural parts.

Wood-filled filament contains wood fibers for a realistic wooden texture and appearance. It is commonly used in decor and crafts.

Metal-filled filament is infused with metal powder for added weight and a metallic finish. It is popular for aesthetic parts and jewelry.

Metal Filaments: Beyond Plastics

Metal 3D printing is typically reserved for Direct Metal Laser Sintering (DMLS) or Metal Fused Filament Fabrication (Metal FFF) processes.

- Stainless Steel: Common in tooling, fixtures, and even jewelry.

- Aluminum and Titanium: Used in aerospace and high-performance applications.

These processes require specialized printers and post-processing but produce functional metal parts suitable for demanding applications (Gibson et al., 2021).

How to Choose the Right Material

When selecting a 3D printing material, consider:

- Functionality: Will the part endure mechanical stress, heat, or wear? For strength, consider ABS, PETG, or carbon fiber composites.

- Detail & Finish: Resins outperform most thermoplastics for smooth surfaces and fine detail.

- Budget: PLA is affordable and sufficient for many prototypes and non-load-bearing components.

- Post-Processing: Resins may require extra steps like curing, while thermoplastics often need minimal finishing.

- End Use: Consider the part's lifespan, environmental exposure, and appearance needs.

Material Selection Examples

|

Application |

Recommended Material |

|

Display model or prototype |

PLA or Standard Resin |

|

Durable mechanical part |

PETG or Carbon Fiber-Filled Filament |

|

Flexible component |

TPU or Flexible Resin |

|

Artistic or decorative part |

Wood-Filled Filament or Metal-Filled Filament |

|

High-stress or industrial application |

ABS, Nylon, or Metal Printing |

Conclusion

The variety of 3D printing materials available today allows designers and manufacturers to tailor each print to its intended use. By understanding each material's properties, costs, and processing requirements, you can make smarter decisions and achieve better outcomes for your projects.

About This Blog

This blog explores topics related to additive manufacturing, digital fabrication, and modern production techniques. It is designed to help makers, engineers, and small businesses navigate the ever-evolving world of manufacturing.

About This Writer

Lewis Brent Parker, Jr., is an engineer, veteran, and entrepreneur who specializes in manufacturing and digital fabrication. Through his work in engineering and small business leadership, he shares practical insights into modern production methods and innovative design practices.

References

- Criswell, A. (2020). Small Business Prototyping: Tools for Designers and Makers. Maker Media.

- Gibson, I., Rosen, D. W., & Stucker, B. (2021). Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing (3rd ed.). Springer.